G Series

Cheng Yi G Series Internal Turning Tools | The Elite Choice for Comprehensive ID Machining

The G-Series Internal Boring Tool product line, manufactured with German materials, covers various internal machining requirements from basic cutting to complex profiling operations. Through rigorous testing, this series demonstrates superior durability compared to renowned brands from the United States, Israel, and Taiwan, providing comprehensive CNC precision internal machining solutions.

Product Series

Cheng Yi's G Series internal turning tools provide a comprehensive range of models and applications, precisely tailored to your diverse machining strategies:

1. High-Efficiency Internal & Face Grooving Series

- GFR Face Grooving Tool & GVR Deep Face Grooving Tool: Specifically designed for face grooving on workpieces. Whether for standard grooves (GFR) or deeper grooves requiring greater depth of cut (GVR), these tools ensure a flat groove bottom, perpendicular side walls, and exceptional precision.

- GGR Internal Grooving Tool: Expertly cuts O-ring grooves, circlip grooves, and other internal rings on the workpiece's inner diameter. Its optimized cutting edge design ensures smooth chip evacuation, effectively preventing chip build-up and enhancing machining stability.

2. Precision Internal Threading Series

- GIL 60° / GIR 55° / GIR 60° Internal Threading Tools: Offers a complete solution for internal threading, covering the two international standard thread forms: 60° (Metric/Unified Standard Threads) and 55° (Whitworth Threads). The ultra-precision ground tips ensure accurate thread profiles and a smooth, bright thread surface.

3. Full-Function Internal Profiling & Boring Series

- GTR Internal Boring Tool: The most versatile standard internal boring tool in the series, offering exceptional rigidity and cutting performance. It's a reliable choice for fine finishing or enlarging internal holes to target dimensions.

- GPR & GQR Internal Profiling Tools: The ideal tools for machining complex internal hole contours and curved surfaces. Their exceptional tracking capability allows for precise execution of various profiling paths, achieving high-difficulty internal diameter shaping.

- GUR Internal Profiling & Flat Bottom Tool: Specifically designed for internal profiling operations requiring a flat bottom, such as corner clearing and profiling at the bottom of blind holes. Achieve complex shapes in a single pass, eliminating secondary machining.

4. Advanced & Specialty Machining Series

- GWR Internal Spherical Tool (NEW!): A highlight of the G Series! Specifically engineered for machining internal R-angles, spherical contours, or complex 3D curved surfaces. Its ball-nose design offers immense machining flexibility, making it an ideal tool for high-value industries like mold making, aerospace, and medical component manufacturing.

- GXR Reverse Internal Boring Tool: The expert for overcoming challenging machining limitations. Used for back boring, chamfering, or machining from the inside outwards, enabling easy completion of areas traditionally difficult to reach.

Representation Of Tiny Tungsten Steel Inner Diameter Turning Tool

SDK Internal Hole Knife Handle

Model : SDK

Model : SDK

GPR Profiling And Boring Knife

Model : GPR

Model : GPR

GTR Internal Boring Knife

Model : GTR

Model : GTR

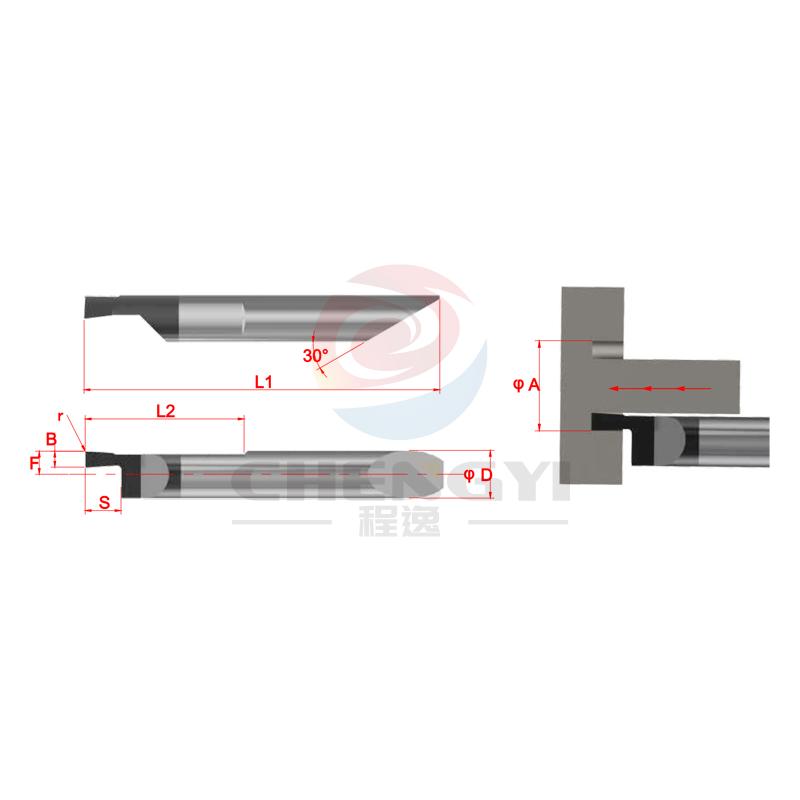

GUR Profiling Flat Bottom Inner Hole Knife

Model : GUR

Model : GUR

GXR Reverse Internal Bore Knife

Model : GXR

Model : GXR

GVR Deep Face Grooving Knife

Model : GVR

Model : GVR

GFR Face Grooving Knife

Model : GFR

Model : GFR

GFL face Grooving Knife

Model : GFL

Model : GFL

GWR Inner Hole Spherical Knife

Model : GWR

Model : GWR

GIL 60° Internal Threading Knife

Model : GIL 60

Model : GIL 60

GQR Profiling Inner Hole Knife

Model : GQR

Model : GQR

GIR 60° Internal Threading Knife

Model : GIR 60

Model : GIR 60

GIR 55° Internal Threading Knife

Model : GIR 55

Model : GIR 55

GGR Inner Hole Grooving Knife

Model : GGR

Model : GGR